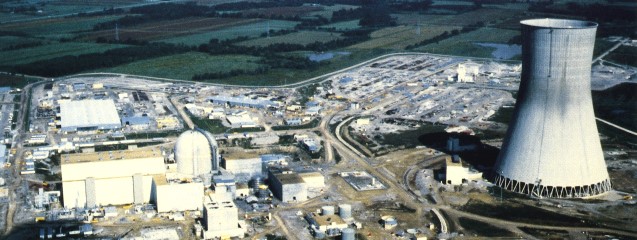

Callaway Nuclear Power Generating Plant

Client:

Callaway, Missouri

Union Electric Company

Location:Callaway, Missouri

Completed by Fluor, the 1150-megawatt Callaway nuclear power plant represented one of the largest and most complex challenges in the company’s nuclear plant construction history. Since commercial start-up, the plant has established a number of records for performance and has consistently been one of the most reliable generating facilities of its kind in the United States.

Client Issues

During the seven years from initial construction mobilization, more than 40 million workhours of craft labor were expended. This facility was one of two built by Fluor under the Standardized Nuclear Unit Power Plant Syndicate concept. It required more than 40,000 drawings from design engineers and 50,000 drawings from vendors. The complexity and extent of the quality control and regulatory compliance procedures were reflected in the involvement of more than 50 federal, state, and local agencies.

Solution

Callaway used a pressurized water reactor system and a turbine generator supplied by others. Fluor executed the work under a project agreement with the local building trades, except for pipefitter craftwork, which was accomplished by Fluor. Fluor resources exceeded 2,700 craft and 1,200 onsite engineers, technicians and staff.

Conclusion

Fluor Constructors International, Inc. (FCII), a subsidiary of Fluor Corporation, performed maintenance and modification activities at the plant after commercial operation began.

Major modifications performed by FCII include installation of permanent neutron shielding around the reactor vessel, and removal of RTD bypass piping. FCII maintenance activities have included reactor vessel removal and reinstallation, steam generator primary manway removal and reinstallation, and in-service inspection support.

Read about other Fluor Constructors projects.

Major modifications performed by FCII include installation of permanent neutron shielding around the reactor vessel, and removal of RTD bypass piping. FCII maintenance activities have included reactor vessel removal and reinstallation, steam generator primary manway removal and reinstallation, and in-service inspection support.

Read about other Fluor Constructors projects.